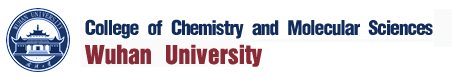

Metal nanoparticles (MNPs) are critical ingredientfor the fabrication of devices on nanoscale. However, solvent, vacuum or inert atmosphere are usually used for the preparation of MNPs, due to their sensitivity to oxygen in air, which limit their application in large scale.A team led byHexiang Deng in College of Chemistry and Molecular Sciences and Gary J. Cheng in theInstitute of Technological Sciences, both from Wuhan University,reported a new method for theproduction ofuniform metal nanoparticles in air using metal-organic frameworks (MOFs) as precursor with laser as the energy source. This method, named asNanoscale Laser Metallurgy and Patterning (nano-LaMP), allows for the printing of MNP patterns in wafer-scale size within tens of seconds, consuming only 5-Watt power (Figure 1), ideally suited for large scale fabrication.

MOFs are constructed by orderly spaced metal ions and carbonaceous linkers. Themetal ions in the structure remain underdeveloped, albeit extensive research on the organic component. In this study, the orderly spaced metal ions and organic linkers in MOF function as metal source and reductant, respectively. The nanosecond pulsed laser precisely deliver patches of energy to MOF crystals. High temperature was generated instantly at local positiondue to the efficient light absorption by MOFs, where metal ions were reduced and sputtered out from the porous structure, followed bycondensed as metal nanoparticles. Nanoparticlesof nine differentmetals, Fe, Co, Ni, Cu, Zn, Cd, In,Pb and Bi, andpatterns were successfully produced from the corresponding MOF crystals by nano-LaMP. Surface enhanced Raman scattering (SERS) chipsconstructed by Cu nanoparticle patterns on glass using this method exhibited exceptionally low detection limit (10-12M) for biomolecules.

The nano-LaMP method combines the advantages of laser and MOFs,offering new choice for the fabrication ofnano-devices in afast, economic, efficient and flexible manner. This work, with the title “Nanoscale Laser Metallurgy and Patterning in Air Using MOFs”, was recently published on the Journal of the American Chemical Societyand selected as one of the cover story, withHaoqing Jiang being the first author. This research supported by National Key R&D Program of China), Natural Science Foundation of China and the Innovation Team of Wuhan University. Shanghai Synchrotron Radiation Facility (SSRF),the Sharing Platform for Large-scale Instruments and the Test Center of Wuhan University provide help in material characterizations.

Article link:https://pubs.acs.org.ccindex.cn/doi/10.1021/jacs.9b00355

Group website:http://hdeng.whu.edu.cn/