On June 14, Nature published the latest research results on liquid metals by the team of Fu Lei from the College of Chemistry and Molecular Sciences of Wuhan University (WHU) and the Institute for Advanced Studies of WHU. The title of the article is “Liquid metal for high-entropy alloy nanoparticles synthesis”.

The first signatory is Wuhan University. Doctoral students Cao Guanghui, Liang Jingjing, and Yang Kena from Fu’s team and Guo Zenglong from Southern University of Science and Technology (SUST) are the co-first authors. Professor Fu Lei, Zeng Mengqi, and Guo Yuzheng from WHU and Associate Professor Lin Junhao from SUST are co-corresponding authors. WHU’s postgraduate Wang Huiliu, doctoral students Wan Xuhao, Li Zeyuan, Zhang Yile, Liu Junlin, Zheng Zhenying, and Lu Cai, undergraduate students He Guangzhi and Xiong Zeyou and Professors Chen Shengli and Liu Ze are co-authors.

High-entropy alloy is a new type of alloy consisting of five or more primary metals, which has significant applications in areas such as structural mechanics, energy conversion and storage, and medical devices under extreme conditions. The foundation of its application is the achievement of atomic-level precision manufacturing of high-entropy alloys. Differences in the physicochemical properties of different elements can limit uniform miscibility between elements, making ideal high-entropy state difficult to obtain, and highly restricting the choice of elements. According to the Gibbs function, the synthesis of high-entropy alloys often depends on harsh high-temperature reaction conditions (increasing the contribution of entropy factor) to overcome the interatomic immiscibility and maintain a high-entropy state through, for instance, quenching. Achieving multi-component atomic miscibility of high-entropy alloys under mild conditions facilitates their scalable and customizable precision manufacturing, an extremely challenging goal.

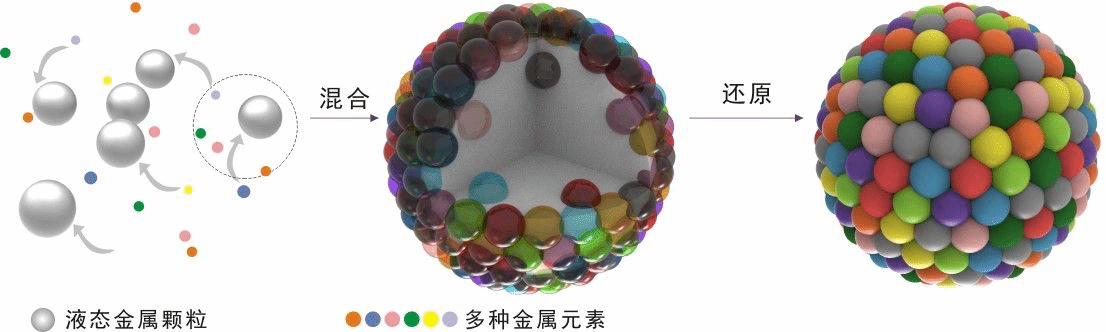

Fu Lei’s team has taken a unique approach to achieving atomic fabrication of various high-enthropy alloy systems under mild conditions by using "mixing enthalpy" as the starting point, reducing the Gibbs free energy change of the reaction and using liquid metals with negative mixing enthalpy and mobility. Liquid metals, such as gallium, have good affinity with most metals and negative mixing enthalpy; they also have good fluidity, which accelerates mass transfer and facilitates the homogeneous dispersion of elements and alloying reactions. As a result, multi-component atomic miscibility of high-entropy alloys can be done under mild conditions in the reaction system of liquid metals, which greatly expands the component selection space for high-entropy alloys and promises to promote their application in more critical areas.

Schematic diagram about the manufacturing of liquid metal high-entropy alloy atom

The research has received support from various sources. Guo Yuzheng’s team from WHU’s School of Electrical Engineering and Automation offered support for molecular dynamics simulations, and Lin Junhao’s team from SUST characterized the sample using spherical aberration high resolution transmission electron microscopy. Professor Chen Shengli and Professor Liu Ze from WHU, Associate Professor Bai Yijia from Inner Mongolia University of Technology and Associate Researcher Feng Yanpeng from Songshan Lake Materials Laboratory and other cooperators provided support during the research process. The research was also supported by the Public Test Platform of WHU and the Shanghai Synchrotron Radiation Facility.

Professor Fu Lei’s research team

Professor Fu Lei instructs students conducting an experiment

Fu Lei’s team has long been devoted to research on atomic manufacturing in the field of material science(leifu.whu.edu.cn), developing liquid metal reaction systems and realizing atomic manufacturing of many types of materials.

Link to papers: https://www.nature.com/articles/s41586-023-06082-9

Rewritten by: Chenyu

Edited by: Li Chenxi