Recently, Advanced Materials, one of the world’s top journals with an impact factor of 27.398, published the latest findings of a cooperative research on nanofibrous aerogels for salt‐resistant solar desalination. The research was conducted by Professor Deng Hongbing’s research group from the School of Resource and Environmental Sciences of Wuhan University (WHU) and Professor Ding Bin’s research group of Donghua University (DHU).

The article is entitled “Cellular Structured CNTs @Sio2 nanonanoels with very-aligned CNTs for Salt-resistant Solar Desalination”.

Dong Xiangyang, a doctoral candidate of the class of 2019 from WHU, and Cao Leitao, a doctoral candidate from DHU, are co-first authors, with WHU as the first author affiliation, and Deng Hongbing and Ding Bin as co-corresponding authors. The research was supported by the National Natural Science Foundation of China and the innovation group of the Natural Science Foundation of Hubei Province.

Water resource and security have long been the hot spot in the field of international resource management and the environment. About 2 billion people in the world suffer from a lack of safe and reliable freshwater supply. In order to ensure an adequate supply of fresh water, solar seawater desalination technology has drawn widespread attention in recent years. But in the process of desalination, the salt on the surface of the evaporator increases as a result of evaporation. Most evaporators’ lack of salt-resistance makes it difficult to remove salt away from the evaporation interface, which causes salt crystallization. The salt crystals can reduce the absorbance and block the transport of water, thus lowering the evaporation rate and even damaging evaporators.

To solve the above problems, Deng Hongbing and Ding Bin collaborated to design a solar evaporator of nanofibers with superior salt-resistance based on the following principles: First, the evaporator should possess a high absorbance to convert as much solar energy as possible into heat. Second, through the regulation of the self-assembly process, the nanofibers are expected to accurately simulate the pore structure and porous vessel walls of biomass fibers, while vertically aligned vessels are established for efficient water and salt transport on that basis. Third, the evaporator must possess enough mechanical strength and chemical stability to ensure the long-term and effective property of evaporation.

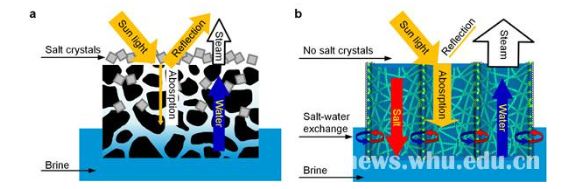

a) Process of water transportation, light absorption, evaporation, and salt crystallization in traditional solar evaporator

b) Process of salt transportation, water transportation, light absorption, and evaporation in the nanofibrous aerogels

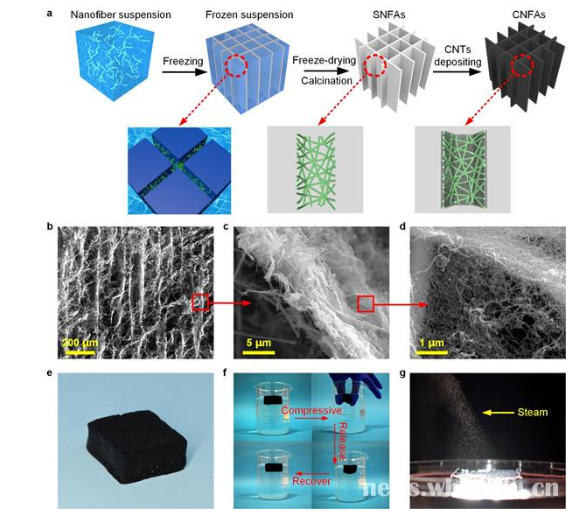

In order to meet the first two requirements, the nanofibers are assembled into aerogels with vertically aligned vessels by freezing the nanofibers to realize efficient salt and water transport. Carbon nanotubes (CNT) are deposited on the vessel wall to achieve a high absorbance through multiple scattering and absorption in the vessels. Besides, flexible electrospun nanofibers-SiO2 are selected as the structural components of the evaporator, therefore the standards of mechanical strength and chemical stability are met.

a) Diagram of the fabrication and structure of the CNFAs

b–d) Microscopic porous structure of the CNFAs under different magnifications.

e) CNFAs with high absorbance

f) Compression and resilience of the CNFAs in water

g) Steam generating from the CNFAs surface

With a light absorbance of 98%, the nanofiber-based solar evaporator exhibits an evaporation rate of 1.50 kg m−2 h−1 under 1 kW m-2 irradiation. No salt crystalizes even in 20% saltwater under 6 kW m-2 continuous irradiation. In addition, by virtue of its excellent mechanical strength and chemical stability, it can withstand repeated compression, long-term ultrasonic and acid-base treatment, and the fresh water it produces meets all drinking water standards of WHO. The harmful components in the wastewater and seawater contaminated by heavy metals, organic dyes and antibiotics are almost completely removed.

In previous reports, evaporators were invariably equipped with hydrophobic top layer and hydrophilic bottom layer. The hydrophobic layer prevents salt crystallization on the surface of the material by hindering the brine from reaching the surface. Instead of preventing its arrival, the study employs a strategy of transporting the salt away. The key structural feature of CNFAs is a hydrophilic vertically aligned vessel made up of SiO2 nanofiber frames. The vertically aligned vessels connect the evaporation interface and the bottom water, ensuring that the salt is transferred along the shortest path from the high-salinity evaporation interface to the low-salinity bottom water through diffusion and convection. Compared with the meandering and winding path of a traditional solar evaporator, the vertically aligned vessel will greatly facilitate the transportation of salt from the evaporation surface to large amounts of water.

Article Link: https://doi.org/10.1002/adma.201908269

Written by: Xu Peng

Rewritten by: Shi Shang

Edited by: Chen Muying, Geng Jinwei,Sylvia and Hu Sijia