Academician Xu Hongxing’s research team made another breakthrough on surface plasmonic sensors, realizing the probing of dimensional changes in nanostructure gap distance with sub-picometer differential resolution. Nature Communicationspublished the achievement in an article titled Probing of sub-picometer vertical differential resolutions using cavity plasmons.

The research was mainly conducted by doctoral student Chen Wen and associate professor Zhang Shunping of Xu’s team, with Xu as the corresponding author. This work was funded by the Ministry of Science and Technology as well as the National Natural Science Foundation of China.

Early in 1997, Xu discovered two close metallic nanostructures in the optical field could generate intense electromagnetic coupling through the nanogap and give rise to plasmon resonances. This is one of the most significant optical effects in nanophotonics and plasmonics as well as the physical basis for many frontier scientific researches. The plasmon resonances can generate enormous electromagnetic amplification in nanogap, accounting for the surface-enhanced Raman spectroscopy of single-molecular sensitivity. Besides, resonance wavelength is ultrasensitive to changes in nanostructure gap distance, which is used to monitor spatial changes in the gap region with a name of “plasmon rulers”. It has already been applied in resolving real-time nanoscale dimensional changes in nano materials and biomolecules including DNA hybridization, enzymic reaction and molecular adsorption, with sub-nanocometer differential resolutions.

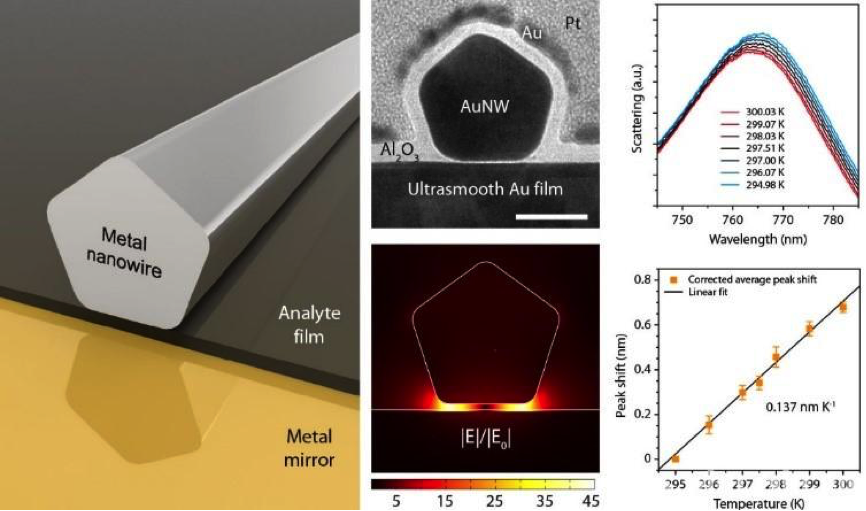

Xu’s research team demonstrates the probing of vertical dimensional changes in a simple gold/silver nanowire-on-mirror (NWOM) plasmonic nanostructure setup that harbors an ultrasensitive cavity-plasmon resonance in the spacer layer separating the nanowire and the mirror. The team probed the slight dimensional changes by tracking the spectral shift of the cavity-plasmon resonance. To display the sensing sensitivity of the system, the team probed dimensional changes in the thickness of the spacer layer (with high expansion coefficient) in response to thermal expansion. As the experiment excludes the effect on resonance peaks by refractive index changes caused by thermal expansion, It shows that such type of cavity plasmons sensors are able to probe vertical dimensional changes in situ with sub-picometer differential resolutions which largely exceed the nanometer resolutions of plasmon rulers reported before, thus hitting a new world record.

Cavity plasmons comprising a metal nanowire, a thin dielectric spacer and a metal mirror in a NWOM setup, and the surface plasmon resonance’s ultrasensitivity to sub-picometer-level gap distance changes.

For the cavity plasmons sensor systems can probe the distance changes with sub-nanocometer resolutions, it is expected to be applied to detection of extremely slight physical and chemical reaction in atomic-scale nano materials in situ, including photoinduced stress, piezoelectric effect, photomechanics, monomolecular adsorption and thermal expansion, or to precision measurement of gravity and pressure effect. The research has pushed forward cavity plasmons sensors to an unprecedented sensitivity, greatly contributing to detecting slight physical, chemical and biological processes, revealing their interior principles and developing relevant new technology.

(Rewritten by Zhong Weile)

(Edited by Zheng Lingling, Shen Yuxi, Liu Jiachen and Liu Xiaoli)